How to Deliver Optimal Indoor Air Quality with HVAC Technology Post-Pandemic

By Dan Fox, PE, CEM, LEED AP BD+C

By Dan Fox, PE, CEM, LEED AP BD+C

A good indoor air quality strategy involves a variety of technologies, and many of them complement each other to maximize total system effectiveness. Here’s a breakdown of how those technologies can contribute to improved indoor air quality.

About the Expert:

Dan Fox, PE, CEM, LEED AP BD+C, directs the Minnesota operations of our mechanical, electrical, and plumbing (MEP) Division. He works on systems for new buildings and renovations for county and state government, hospitals and clinics, multi-use facilities, and commercial buildings – and provides engineering guidance to clients evaluating technologies for systems in current operation, new systems for future consideration, or projects currently under construction.

But first, what contaminants are measured that when removed improve indoor air quality?

- The contaminants most targeted for indoor building environments are volatile organic compounds (VOCs) and particulate matter, both 10 microns in size and 2.5 microns in size, often referred to as PM10 and PM2.5.

- Other contaminants in either industrial environments or considered for general health concern include carbon dioxide, carbon monoxide, lead, nitrogen dioxide, odors, ozone, formaldehyde, radon, and sulfur dioxide.

Monitoring VOCs is important because these contaminants come from the off gassing of many new building materials, as well as many chemicals used in buildings. Monitoring PM2.5 concentration is important because many contaminants, including viruses, VOCs, and smoke – including engine exhaust – have molecules this size. The size of the particulate is important because the natural protections of the human lungs allow this size to be absorbed directly to the smallest lung passageways.

How Does Ventilation Technology Contribute to Indoor Air Quality?

In response to COVID-19, the American Society of Heating, Refrigerating and Air-Conditioning Engineers’ (ASHRAE) recommendation is to evaluate HVAC systems to maximize the amount of ventilation air each system can provide without sacrificing temperature or humidity control. Studies have shown that keeping people comfortable is the first step in keeping people healthy and to promote strong immune systems.

Keeping indoor air pollutants at low levels through dilution of the introduction of ventilation air into commercial buildings is the whole goal of ASHRAE Standard 62.1. This strategy can cost building owners in energy. Equipment has limitations for how much outside air it can handle, but this is a good first strategy to consider for any building owner. Owners should not sacrifice indoor temperature and humidity control by bringing in more outside air than their equipment is able to condition properly.

How Does Filtration Technology Impact Indoor Air Quality?

Standard filters are rated with a MERV rating, which is a minimum efficiency reporting value. The higher the MERV rating, the more efficient the filter is at capturing smaller contaminants.

MERV values in the range of 1-4 generally capture pollen, dust, and carpet fibers greater than 10.0 microns. These filters are generally considered throwaway filters and can also be made of a washable aluminum mesh. These types of filters are typically found in window air conditioners. The ratings move up from there.

- MERV 5-8 filters are used on typical residential furnaces, usually 1-inch-thick cardboard frames and pleated. They capture particulates like mold, cement dust, and spores 3.0-10 microns in size.

- MERV 9-12 filters are found in commercial buildings, can be 4-12 inches thick and bag filters. They capture legionella, flour, and coal dust that is 1.0-3.0 microns.

- MERV 13-16 filters are generally found in hospitals or superior commercial buildings and are similar type of bag filter or box filter. They capture all bacteria, most smoke, and sneeze droplets that are between 0.3-1.0 microns in size.

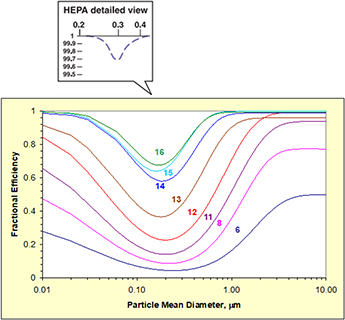

The next higher rating of filtration gets into HEPA filters (high efficiency particulate air) or UEPA (ultra efficiency particulate air). See Figure 1 for a graph of filter efficiency and particle size listing each MERV rating with HEPA filter rating at the top.

Improving filtration is a good option for building owners to consider with respect to the capabilities of their existing HVAC systems, but there are limitations to what fan capacities can handle. In general, a higher MERV filter will generate higher pressure drop and require more fan power to move the same amount of air. Building owners should not sacrifice a decreased fan airflow rate for higher efficiency filters. The filters only catch particles that are entrained in the air getting back to the HVAC system.

What Role Does UV Technology Play in Indoor Air Quality?

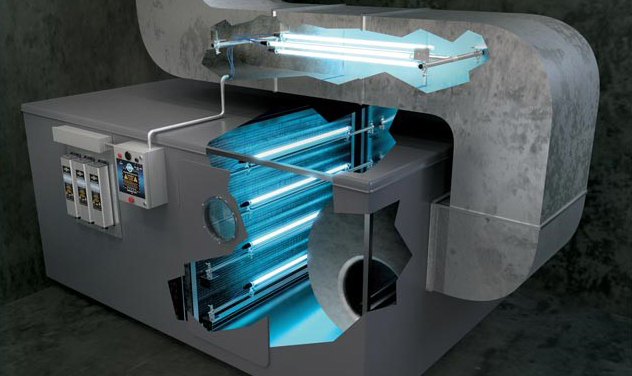

Ultraviolet energy inactivates viral, bacterial, and fungal organisms so they are unable to replicate. This strategy has been traditionally incorporated into central station indoor air handling unit HVAC systems with UV linear tube bulbs installed downstream of cooling coils. In this position, they shine UV light on the wetted surface of the coil and the drain pan. The direct impact of the right UV wavelength photon will kill and prevent the replication of mold caught on the wet surfaces.

An example of this type of installation is shown in Figure 2 looking inside the equipment showing the four tubes shining on the coil and the drain pan down below. The level of intensity of UV light shown in this picture is meant to operate 24 hours per day, seven days a week. This long exposure time allows this low-intensity UV light to inactivate organisms and keep the cooling coil and drain pan free of mold and bacteria. This type of design does not have enough intensity to inactivate any airborne pathogens or particles suspended in the air that fly by the coil and on through the rest of the HVAC system.

Another application of UV technology using all the same components is to design the system for a “fly by” strategy, where there is enough intensity to inactivate viruses with a shorter exposure. See Figure 3 below for an example installation in a similar type of setting. Notice there is about 10 times the amount of light. This strategy, like filters, relies on the airflow patterns and distribution in the space to catch particles that are entrained in the air returning back to the HVAC system and exposing pathogens to the high-intensity UV light.

There are also other UV technologies that apply UV lights in the room for upper room application or in-room for surfaces. UV can degrade materials so compatibility or shielding needs to be considered. It is also an eye and skin irritant so proper protective equipment needs to be used to limit or eliminate exposure.

UV bulbs have approximately 6,000-10,000-hour life, so they need to be changed out every year. Not all lamps are the same, as some can produce harmful ozone and should be avoided, but others can address these concerns and are ozone free. Application of UV technology should not replace ventilation and filtration strategies, but they complement each other and work together.

How Does Ionization Technology Impact Indoor Air Quality?

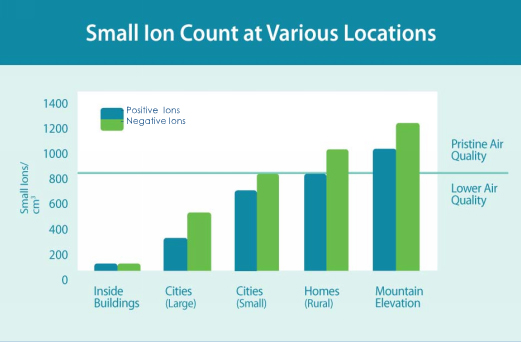

Bipolar ionization and needlepoint bipolar ionization technology uses the power of ion particles to attach to and inactivate contaminants that it comes in contact with. Ions are charged particles that are found in nature where the air has the least number of contaminants, like up in the mountains and where the ocean meets the shore or around waterfalls.

Ions are created and introduced into the supply ductwork of HVAC systems and distributed with the supply air to each space, cleaning the air in the process. This air then distributes ions in the space reacting with contaminants at their source in the room.

See Figure 4 for examples of ion concentration levels found in nature, as well as inside buildings.

The lack of ions in the space can cause the number of contaminants to build up inside. Artificially creating and distributing these ions is how this technology reduces the number of contaminants and inactivates harmful chemicals.

There are many studies that show creating these ions reduces dust, reduces the particulate matter, reduces odors, reduces mold, and kills bacteria and deactivates viruses. Cleaner air also reduces the need to over ventilate spaces, saving energy in the process.

Which HVAC Distribution Strategies Help with Indoor Air Quality?

How air is introduced into each space, where it travels, how it mixes, how it delivers ventilation air, and how it conditions all play a role in airborne pathogen control. A deeper look into how HVAC system design is incorporated into a variety of spaces will require special consideration in our industry moving forward.

The experts in our Mechanical, Electrical, Plumbing (MEP) Division are equipped to handle a variety of HVAC design challenges on a variety of building types, working to develop solutions that meet client needs within their budget. Some strategies that we think will gain more traction because of how they work and the benefits they offer are underfloor air distribution systems, displacement ventilation, dedicated outdoor air systems, source capture, and negative pressure, among others.

Why is Indoor Air Quality Important?

Superior indoor air quality is essential to keeping people healthy and safe in indoor environments. There are a number of great strategies to use to address many indoor air quality concerns with cost-effective solutions, like ventilation, filtration, UV lights, and ionization. How they get implemented needs engineering expertise.

For more information regarding HVAC technology and indoor air quality, contact Dan Fox, PE, CEM, LEED AP BD+C, or any the experts in our MEP division.

Post a comment: