Dam Safety Starts with Careful Inspections

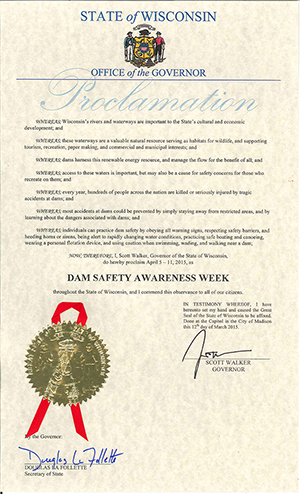

It’s Dam Safety Awareness Week in Wisconsin, and state residents and visitors are being reminded to be careful around dams by staying alert to changing conditions and obeying all warning signs. And while those are crucial safety tips, there’s another element to ensuring dam safety: The dams themselves need to be safe.

It’s Dam Safety Awareness Week in Wisconsin, and state residents and visitors are being reminded to be careful around dams by staying alert to changing conditions and obeying all warning signs. And while those are crucial safety tips, there’s another element to ensuring dam safety: The dams themselves need to be safe.

The Wisconsin Department of Natural Resources administers the Owner Responsible Inspection Program (ORIP), which mandates that dams be regularly inspected by experienced professional engineers. The bigger the dam and the higher the potential hazard if it fails, the more often it must be inspected. (You can access the WDNR dam safety website here and read the WDNR’s list of frequently asked questions here.)

The Wisconsin Department of Natural Resources administers the Owner Responsible Inspection Program (ORIP), which mandates that dams be regularly inspected by experienced professional engineers. The bigger the dam and the higher the potential hazard if it fails, the more often it must be inspected. (You can access the WDNR dam safety website here and read the WDNR’s list of frequently asked questions here.)

That’s where Ayres Associates comes in. Our Wisconsin-based water resources staff specializes in dam inspection and design, and they know what to look for to keep dams in good repair and protect the surrounding area from dam failures. Wisconsin has more than 900 state-regulated large dams, according to the WDNR, with 190 of them classified as high hazard and needing inspections every two years and more than 100 classified as significant hazard and needing inspections every three to four years. Lower hazard dams need inspection every 10 years. That means each year on average, 186 Wisconsin dams need an inspection by a professional engineer.

“We act as the WDNR’s eyes,” explains Pete Haug, one of our water resources engineers. “We observe the dam and write a list of things we believe are deficient or need further investigation. We look for changes in a dam’s shape – is the slope slumped (think of a slow mudslide), are the structures sliding (moving slowly downstream)? We look for limited hydraulic capacity – can the dam pass enough flood water to keep the dam from overtopping and washing away?”

The accompanying photo is an example of leakage around stoplog slots. Pete explains that once the riser (vertical) pipe wall starts to corrode, the leakage could enter the dam embankment and start “piping” soils, eventually tunneling through the dam and collapsing the embankment. He says piping failures are one of the top three causes of dam failure.

The accompanying photo is an example of leakage around stoplog slots. Pete explains that once the riser (vertical) pipe wall starts to corrode, the leakage could enter the dam embankment and start “piping” soils, eventually tunneling through the dam and collapsing the embankment. He says piping failures are one of the top three causes of dam failure.

Pete notes that when many dams were built, the areas surrounding them were much less populated. As more people move into an area, a dam needs to be able to pass more water without overtopping.

Pete points to the Lake Delhi Dam in eastern Iowa as an example of a dam failure that regular inspections could have helped to prevent. “The dam washed out in 2010 because the gates could not open properly,” he says. “A dam’s gates are normally closed, and if you don’t inspect them to make sure they work, when a flood comes, you don’t have time to repair deficiencies. For Lake Delhi Dam, a flood breached the dam and washed it out, partly because Iowa doesn’t have ORIP – each of their state dam safety staff is responsible to inspect 1,287 dams! Wisconsin’s ORIP program means dam safety inspectors are only responsible for 10 or 20 dams so that all dams in the state get their allotted safety checkup.”

(For technical details about the Lake Delhi Dam failure, click here.)

We’ve also helped clients by designing repairs for their dams as well as helping them with grant applications to pay for the costs of those repairs. For example, we helped Adams County with applications for the WDNR Municipal Dam Grant Program to repair plugged toe drains on one dam and flatten the slope of another.

Interested in more about dam safety? Contact our experts.

Post a comment: