Waunakee Alloy Grant, ESAs & Remediation Services

« Return to Project SearchThe Village retained Ayres to complete an environmental investigation at the Waunakee Alloy foundry site to determine the need for remediation before site redevelopment, ultimately paving the way for construction of a new public library at the formerly blighted site. Before Waunakee Alloy operation ceased in 2009, the property was used for a non-ferrous metal foundry casting operation and rolling mill machinery.

The alloy casting company was built in 1953, and six additional buildings were progressively added through 1982. The structures were used for manufacturing, organization, storage, and administration of the Waunakee Alloy Casting Corporation. Arc furnaces were located in the main building/foundry building and used extensive electricity to melt metal, similar to the arc welding process. Scrap pieces from other steel mills were brought to the foundry in drums and melted down to create new alloy castings.

Ayres prepared grant applications and secured brownfield grants from the Wisconsin Economic Development Corporation (WEDC) for investigating and redeveloping the property. The site was enrolled in the Voluntary Party Liability Exemption (VPLE) program to obtain an exemption from state environmental liability after the site investigation and remediation are completed.

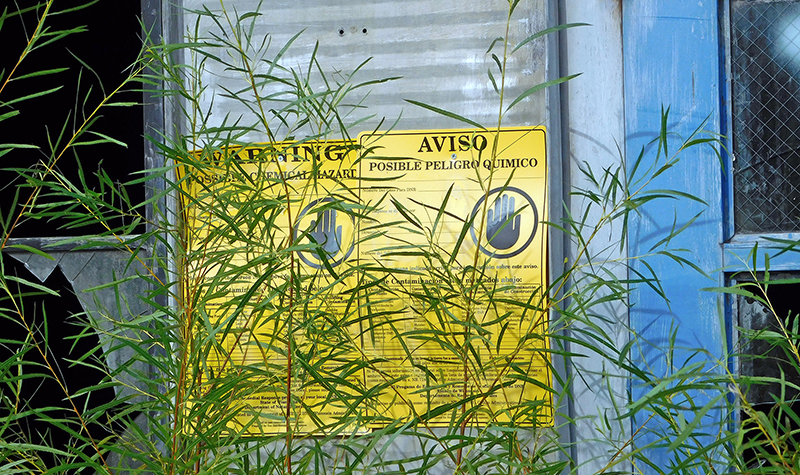

During the Phase 1 environmental site assessment (ESA) and pre-demolition hazardous materials assessment of the property, Ayres discovered large quantities of free elemental mercury and leaking PCB-contaminated capacitors inside the facility. A hazardous waste contractor was retained to place the PCB capacitors into drums and to vacuum the elemental mercury and mercury-contaminated foundry sand into drums. Ayres worked with the Wisconsin Department of Natural Resources (WDNR) and U.S. Environmental Protection Agency (EPA) removals program to dispose of the mixed (TSCA/RCRA) mercury-PCB waste. Handling and disposal of the mixed PCB-mercury waste is problematic, as current federal regulations require incineration of the high-PCB concentrated capacitors but ban the incineration of mercury.

Ayres performed hydrogeologic investigations at the Waunakee Alloy facility to assess the degree and extent of subsurface impacts from the use and disposal of hazardous materials at the site. Ayres negotiated the scope of work and prepared CERCLA level management plans (quality assurance project plan, sampling and analysis plan, and health safety plan) outlining the details of the investigation and remediation program. Investigation activities included surficial soil sampling, corehole sampling within the interior of the building, advancement of soil borings, installation of monitoring wells, hydraulic conductivity testing, low-flow groundwater sampling, soil and groundwater analysis, and analysis of remedial options.

Project Information

Client's NameVillage of Waunakee

LocationWaunakee, WI

Primary ServiceEnvironmental

MarketLocal Government